FREE SHIPPING OVER $20

Free Shipping Inside The USA

MONEY BACK GUARANTEE

30-Day Money Back Guarantee.

MADE IN THE USA

100% American Made Products.

Sale

CoverShield P650 FS – Polyaspartic Floor Coating For Concrete

- Location : Interior/Exterior

- Task : Fast set UV Resistant Coating

- Application : 3/8th Nap Roller/Squeegee

- Base : Solvent Based

- Coverage : 150- 200 sq.ft/Gal.

- Finish : Clear Gloss

- Secure Checkout

- Location : Interior/Exterior

- Task : Fast set UV Resistant Coating

- Application : 3/8th Nap Roller/Squeegee

- Base : Solvent Based

- Coverage : 150- 200 sq.ft/Gal.

- Finish : Clear Gloss

Delivery Time: Typically 3 to 5 business days

Frequently Bought Together

CoverShield P650 FS – Polyaspartic Floor Coating For Concrete

$14.00 – $1.055.00

In stock

- Description

- Product Quantity Calculator

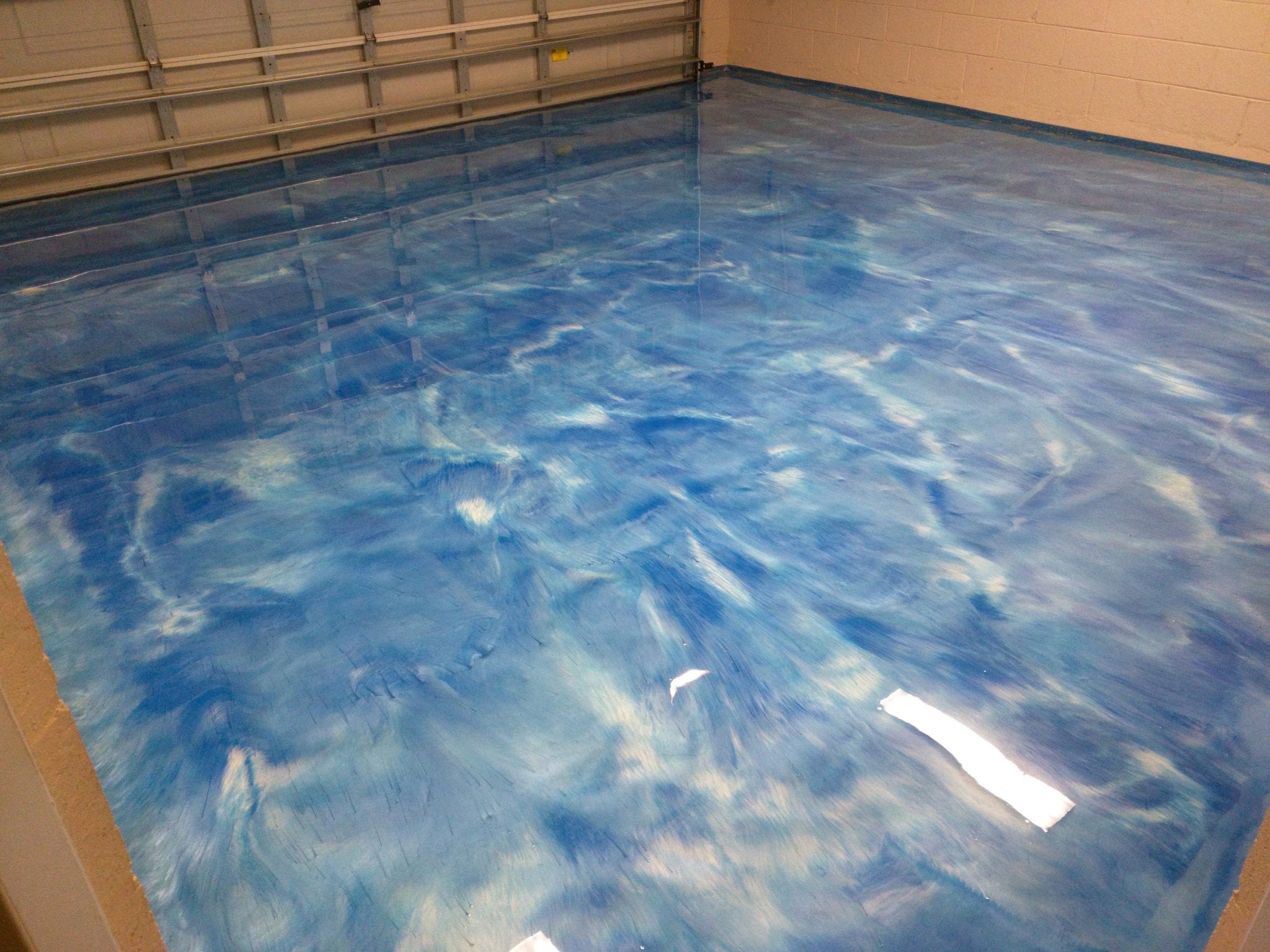

- Gallery

- Technical

- Reviews

Description

UV resistant fast set polyaspartic coating

CoverShield P650 FS Polyaspartic Floor Coating

CoverShield P650 FS is a fast set two-component 85% solids aliphatic polyaspartic coating. It has a high gloss finish, excellent non-yellowing UV resistance and outstanding impact and abrasion resistance. It dries quickly for rapid return to service applications and for same-day application of multiple coats.

P650 FS has an Easy mix ratio of One-part resin to One-part catalysts by volume and can be used for interior or exterior applications.

Features

- Fast turn around

- Color and UV stable

- Hygienic seamless surface

- Excellent impact resistance

- Abrasion-resistant top coat

- Good chemical resistance

Main Uses

- Topcoat for UV stability

- Clear binder for color flakes and quartz

- Floors, internal and external

- Parking decks and driveways

- Garage floors and workshops

- Balconies and walkways

Surface Conditions

Grind concrete floors to CSP-3, vacuum dust, wipe down with denatured alcohol. If moisture is present floor may require the application of WaterStop Primer at a spread rate of 150-300 sq. ft. per gallon.

e surface being coated must be fully cured 28 days, structurally sound (200psi or greater according to ASTM D4541), clean (ASTM D4258), and dry (less than 5%, ASTM D4263). It must have low moisture-vapor transmission (less than 3lbs/24 hr/1,000ft2, RMA Test Method). Profile surface according to ICRI Guide 03732 to a minimum of CSP 3.

Mixing

Mix Ratio: 1A:1 B. Combine Part B and Part A in a mixing container. Thoroughly mix both parts with a slow-speed drill and mixing blade for a minimum of 2 minutes. One mixed product has approximately 15 minute Pot Life. Don’t mix more material than can be applied in 15 minutes.

Application

Apply in a single coat at the specified application rate (see above) thickness

When used as a standalone system, apply by brush, 3/8” (10mm) nap mohair roller, or HVLP spray. Two 6mil (0.15mm) coats are normally required. Allow the first coat to dry for a minimum of 1 hour minutes and a maximum of 4 hours before applying the finish coat.

For best results Pour mixed material on the floor in 12” ribbons and then while wearing spiked shoes roller with a 3/8” premium lint-free roller.

Coverage

180-260ft2per gallon depending on substrate and desired surface texture.

Dry Time

Tack free/foot traffic: 4-6 hrs.

Heavy foot traffic 24 hrs. Vehicular Traffic 48 hrs.

Top coat or recoat

Lightly sand the surface and wipe down with denatured alcohol or acetone before applying additional coats or finish coats.

This product is exclusively for contractors.

Contact us for a special offer

| Product Name | Surface Type | Coverage | Size of Area (sq ft) | Recommended Quantity |

|---|---|---|---|---|

CoverShield P650 FS – Polyaspartic Floor Coating For Concrete CoverShield P650 FS – Polyaspartic Floor Coating For Concrete

|

Smooth Surface | 200 sq. ft. per gallon | ||

CoverShield P650 FS – Polyaspartic Floor Coating For Concrete CoverShield P650 FS – Polyaspartic Floor Coating For Concrete

|

Textured Surface | 150 sq. ft. per gallon |

- The recommended amounts are approximate only, and are for One (1) application.

- Check product data for recommended number of applications.

- Test product on actual surfaces to determine exact coverage rates.

CoverShield P650 FS Technical Data Sheet

CoverShield P650 FS Safety Data Sheet

What customers are saying

Related Products

Terrazzo, Burnished & Polished, Concrete & Terrazzo, Driveways, Driveways & Sidewalks, Hospitals, Natural Stone, Patios & Pool Decks, Pavers & Natural Stone, Penetrating Concrete Sealers, Penetrating Sealers, Penetrating Sealers, Restrooms & Showers, Sidewalks & Walks, Troweled Concrete

Stone Impregnator Sealer - CoverSeal Premium with Maximum Stain Resistance

$14.00 – $485.95

Terrazzo, Colors / Stain / Flakes, Concrete & Terrazzo, Concrete Colors/Flakes, Concrete Pavers, Driveways, Driveways & Sidewalks, Exposed Aggregate, Patios & Pool Decks, Pavers & Natural Stone, Sidewalks & Walks, Troweled Concrete

ColorStain UV Resistant Liquid Stain Concentrate for Concrete

$14.00 – $274.00