FREE SHIPPING OVER $20

Free Shipping Inside The USA

MONEY BACK GUARANTEE

30-Day Money Back Guarantee.

MADE IN THE USA

100% American Made Products.

Oil Resistant Concrete Sealer – CoverShield U140 Gloss Finish

- Location : Interior/Exterior

- Task : Floors

- Application : Pump Sprayer, MIcrofiber Mop, T-Bar, Roller

- Base : Water Based Urethane

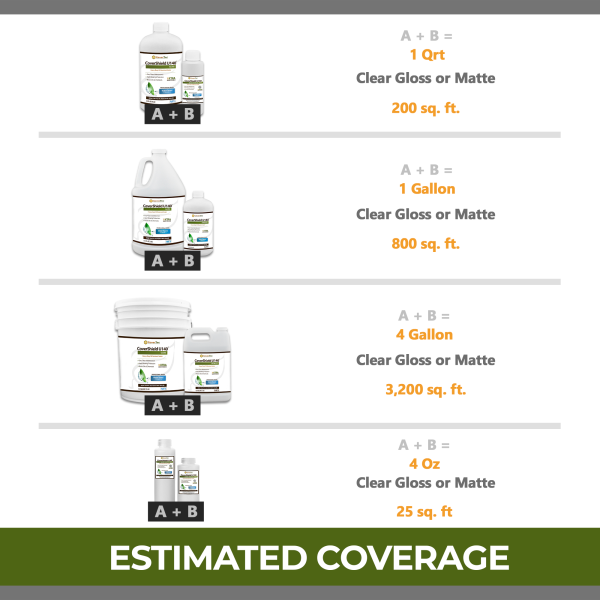

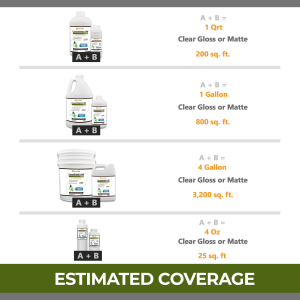

- Coverage : 800 sq.ft/ gallon (19 .6 sq.m/l)

- Finish : Gloss

- Secure Checkout

- Location : Interior/Exterior

- Task : Floors

- Application : Pump Sprayer, MIcrofiber Mop, T-Bar, Roller

- Base : Water Based Urethane

- Coverage : 800 sq.ft/ gallon (19 .6 sq.m/l)

- Finish : Gloss

Delivery Time: Typically 3 to 5 business days

Frequently Bought Together

Oil Resistant Concrete Sealer – CoverShield U140 Gloss Finish

$14.00 – $471.50

- Description

- Application

- Product Quantity Calculator

- Gallery

- Technical

- FAQs

- Reviews

Description

CoverShield U140 Gloss Heavy Duty Stain & Oil Resistant Concrete Sealer

CoverShield U140 Gloss - Product Video

CoverShield U140 Gloss - Unboxing Video

What Is CoverShield U140 Gloss Concrete Sealer

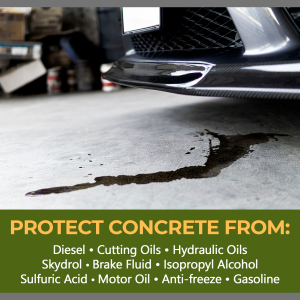

CoverShield U140 is a heavy duty oil resistant concrete sealer. It’s a water-based, polyurethane sealer that is highly stain resistant and provides a very effective resistance to:

- Oil

- Acid

- Chemical stains.

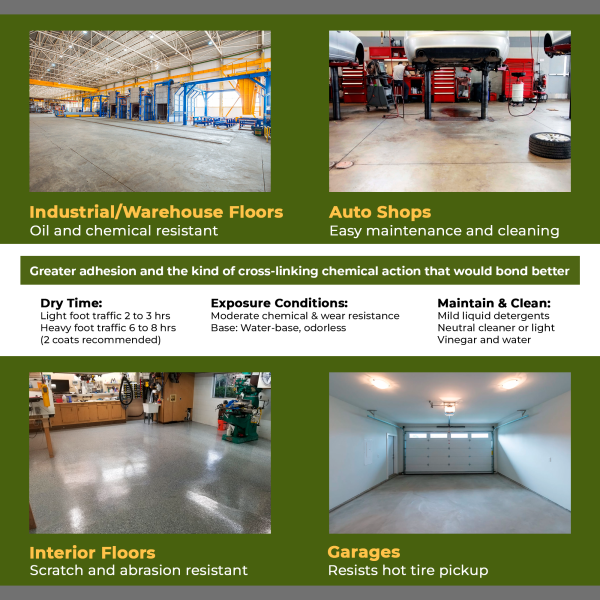

We recommend using it mainly for interior applications such as:

- Trowel finished concrete

- Smooth concrete.

CoverShield U140 oil resistant concrete sealer also has strong industrial uses due to it’s ability to resist and repel:

- Diesel

- Hydraulic motor oils

- Cutting oils.

Features

- Scratch resistant

- Oil and stain resistant

- Odorless

- UV stable

- Easy to apply

- Chemical resistant

- Waterproof

- Excellent abrasion resistant

Typical Uses

- Industrial floors

- Parking decks

- Workshops

- Walkways, stairways

- Counter tops

- Driveways

Warehouse Owner Erik T. Shares His Story About Using CoverShield U140

In factories where cutting fluids and lubricating oils are used, it’s a challenge to prevent those chemicals from penetrating the slab. CoverShield U140 has no problem repelling these from entering a concrete surface.

CoverTec’s U140 oil resistant concrete sealer clearly offers contractors and DIY-ers more bang for the buck because it:

- Requires very little surface surface prep

- Provides higher a coverage area

- Is extremely easy to application.

EPA Rules, Factory and Safety, OSHA, Customers Or Workers

Situations like:

- OSHA & EPA regulations

- Potential contamination areas

- Clean rooms

- Safety areas.

Best Applications For U140 Concrete Sealer

The most suitable applications for CoverShield U140 are:

- Concrete floors

- Smooth concrete

- Trowel finished concrete

- Machine finished concrete

- Polished concrete.

What Is CoverShield U140 Gloss Concrete Sealer

CoverShield U140 outperforms epoxy solutions in every way.

- Diesel

- Cutting oil

- Motor oil

- Gasoline

- Hydraulic fluids

- Jet fuel

- Etc.

- Parking decks

- Loading docks

- Driveways

- Access ways

- Ramps.

Important Note:

If you’re dealing with a rough or broom finish concrete surface, a penetrating sealer like CoverTec’s PEN 55 may be more appropriate. It’s also very oil and stain-resistant but works better in those highly textured environments.

Applying CoverShield U140 - Recommended Steps

At CoverTec, our customers use the term “thin to win.”

It’s all about thin coats. Two thin coats is the minimum requirement for any application. You can also spray down the product, and then spread it thin. You can choose to pour it out on the surface, and then spread it around with a flat mop. If you’re doing large areas, I would recommend using a 3/8th Nap roller – preferably 18 inches wide. This way, you get more efficient production.

Here is something to watch out for:

If the temperature is low… everything takes longer. Once you’re below 70 degrees (Fahrenheit), the dry time can double. In extreme cases, you could need 6 to 12 hours before the first coat dries.

Important Note:

Make sure the first coat is completely dry before you apply the second coat.

Oil Resistant Concrete Sealer - The Best Way to Protect Warehouse, Auto Shop and Industrial Concrete Floor Surfaces

A Key Point About Oil-Resistant Concrete Sealers

What is an Oil Resistant Concrete Sealer?

- According to a 2018 study, an acrylic-based sealer was found to be most effective in protecting concrete against water, oil and abrasion.

- An epoxy-based sealer is highly resistant to chemicals and solvents, making it a suitable choice for oil resistance in concrete sealers.

- Polyurethane based sealers offer the highest level of protection against oil, water, and abrasion, as well as providing a durable finish that resists degradation over time.

Types of Sealers

Topical Sealers

Penetrating Concrete Sealer

Critical Takeaways For Achieving Oil Repellent Concrete

Benefits of Using Oil Resistant Concrete Sealers

Protection from Dangerous Fumes

How to Choose the Right Oil Resistant Concrete Sealer

The Lasting Durability of Your Sealed Surface

Applying an Oil Resistant Concrete Sealer

Creating a Strong Adhesion

What to Look For in an Oil Repellent Concrete Sealer

Conclusion

Frequently Asked Questions

Applying oil resistant concrete sealer is a surprisingly simple process. First, make sure the area to be sealed is completely dry and clean from any dirt, debris or other contaminants. Next, apply the sealer with a brush, roller, or pump sprayer.

For applying penetrating sealer to vertical surfaces, start at the highest point of the surface and work your way down in overlapping strokes in one direction. Allow it to sit for 15-30 minutes before beginning the next step. Finally, go over the same area with a clean terry cloth mop or other applicator to smooth out any uneven areas and ensure an even coverage. This will ensure that the sealer adheres effectively and gives the maximum level of protection against oil staining.

Yes, there are environmental concerns related to using oil resistant concrete sealer – unless it’s water-based. The chemical components used to make the sealer can be harmful to the environment if not disposed of properly. These components are often made from volatile organic compounds (VOCs), which can contribute to air pollution and increase greenhouse gas emissions.

Additionally, it is important to note that some of these chemicals may also be toxic if ingested or absorbed through skin contact. For this reason, proper precautions should be taken when using oil resistant concrete sealer outdoors, including wearing protective clothing and utilizing proper breathing apparatuses. Lastly, it is essential that the product is disposed of in accordance with local laws and regulations to ensure minimal environmental impact.

Oil resistant concrete sealer is designed to last and provide protection for your concrete surfaces over time. Generally, the performance of oil resistant concrete sealers will vary depending on the type of sealer used and environmental factors, but most quality brands can protect concrete surfaces for up to 10 years when applied correctly.

The best way to ensure the longevity of oil resistant concrete sealers is to use a quality product from a reliable source and apply it following the manufacturer’s instructions carefully. Additionally, regular maintenance such as periodic cleaning, resealing, and repairs should also be done to help keep your concrete surfaces protected for longer periods of time.

CoverShield U140 Semi Gloss Videos

| Product Name | Surface Type | Coverage | Size of Area (sq ft) | Recommended Quantity |

|---|---|---|---|---|

Oil Resistant Concrete Sealer – CoverShield U140 Gloss Finish Oil Resistant Concrete Sealer – CoverShield U140 Gloss Finish

|

Smooth Surface | 800 sq. ft. per gallon | ||

Oil Resistant Concrete Sealer – CoverShield U140 Gloss Finish Oil Resistant Concrete Sealer – CoverShield U140 Gloss Finish

|

Textured Surface | 400 sq. ft. per gallon |

- The recommended amounts are approximate only, and are for One (1) application.

- Check product data for recommended number of applications.

- Test product on actual surfaces to determine exact coverage rates.

CoverShield U140 Gloss Technical Data Sheet

CoverShield U140 Semi Gloss Safety Data Sheet

CoverShield U140 Cleaning and Maintenance

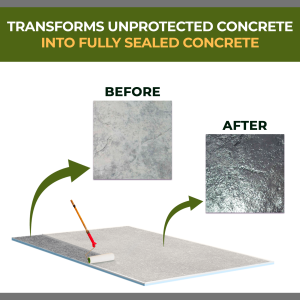

U140 does not require extensive surface preparation in order to bond to a smooth surface. This makes the product very effective on smooth steel troweled, densified or polished concrete. The high coverage per gallon.( 800 sq. ft /gal or greater) compared to 150 -200 sq. ft per gal for an epoxy coating . This makes the U140 a high-performance high value solution. A lot of bang for the buck!

Epoxy coatings have excellent oil and chemical resistance but are not UV resistant and are for interior use only. Application thickness is higher and surface preparation needs are greater for an epoxy . This drives up the overall cost of and epoxy coating compared to the CoverShield U140.

A major benefit of the CoverShield U140 is that it is a thin film system. It penetrates the sub surface and leaves a thin film on top of the concrete. This film is very oil resistant and makes concrete easy to clean and maintain. Also, it does not flake and peel like epoxy.

Having said that U140 is a very durable sealer and has a high scratch resistant. If the surface does get scratched it is easy to repair. Sand the damaged area with 400 grit sandpaper. The aim is to feather out the scratch and prepare the repair area for to coating. Then wipe up the dust using neutral cleaner or rubbing alcohol. The repair area needs to clean dull and dry. When dry apply 2 or 3 thin coats of U140 . Allow 24 -48 hours before opening to vehicular traffic depending on temperature and humidity.

Penetrating sealers do not form a film at the surface. The work by blocking the pores in the concrete and restricting the oil and other contaminates getting into the sub surface of the concrete. The very top surface is still exposed however so staining is still possible and there are limitations to the amount of oil exposure the penetrating can withstand.

In a workshop environment or where there is heavy vehicular traffic, floor surface should be mopped daily or cleaned with a floor machine using a neutral cleaning solution.

If the surface is polished (maximum 800 grit ) or very dense we recommend you apply a prime coat first. Apply the prime coat by pump up spray only. No mopping.

If the surface is very textured uneven or broom finished, then a U140 should be applied by 3/8th nap microfiber roller. Please refer to the technical datasheet for more in depth application instructions.

It is very important to make sure that the concrete is absorbent. Any existing sealer or curing agent etc. that might interfere with the absorption of the u140 sealer should be removed. A quick test for existing sealers is to conduct a water test to see if the concrete will darken when wet. Simply pour 1 fl.oz of water on the concrete and see if it will darken the surface after standing for 5 minutes. If after 5 minutes the surface does not darken prepare the surface by sanding the floor with a 60-200 grit sanding screen or diamond abrasive pad. Remove all residue before sealing.

In a workshop environment or where there is heavy vehicular traffic, the floor surface should be mopped daily or cleaned with a floor machine using a neutral cleaning solution.

What customers are saying

Related Products

CoverShield P650 FS - Polyaspartic Floor Coating For Concrete

Silane Siloxane Sealer - CoverSeal Pen50 Water, Salt, Mold and Mildew Resistant Coating